Exploring The Surprising Sound Absorption Abilities Of Polyester Fiber

Welcome to our exploration of the fascinating sound absorption abilities of polyester fiber. In a world where noise pollution is becoming an increasingly prevalent issue, the potential for a simple material like polyester to mitigate unwanted sound is truly surprising. Join us as we delve into the science behind this phenomenon and uncover how polyester fiber could revolutionize the way we think about acoustic performance. Let's uncover the unexpected potential of polyester fiber in the realm of sound absorption.

- Introduction to Polyester Fiber as a Sound Absorber

When it comes to sound absorption materials, most people think of traditional options such as foam panels or acoustic tiles. However, polyester fiber is emerging as a surprising contender in the world of sound absorption. In this article, we will explore the unique qualities of polyester fiber that make it an effective sound absorber.

Polyester fiber, also known as polyethylene terephthalate (PET), is a synthetic fiber made from a type of plastic. It is commonly used in the textile industry for its durability, wrinkle resistance, and moisture-wicking properties. However, recent studies have shown that polyester fiber also has impressive sound absorption abilities.

One of the key factors that contribute to polyester fiber's sound absorption capabilities is its porous structure. The fibers are densely packed together, creating numerous air pockets that can trap sound waves and reduce reverberation. This is particularly beneficial in environments where noise control is important, such as recording studios, conference rooms, and theaters.

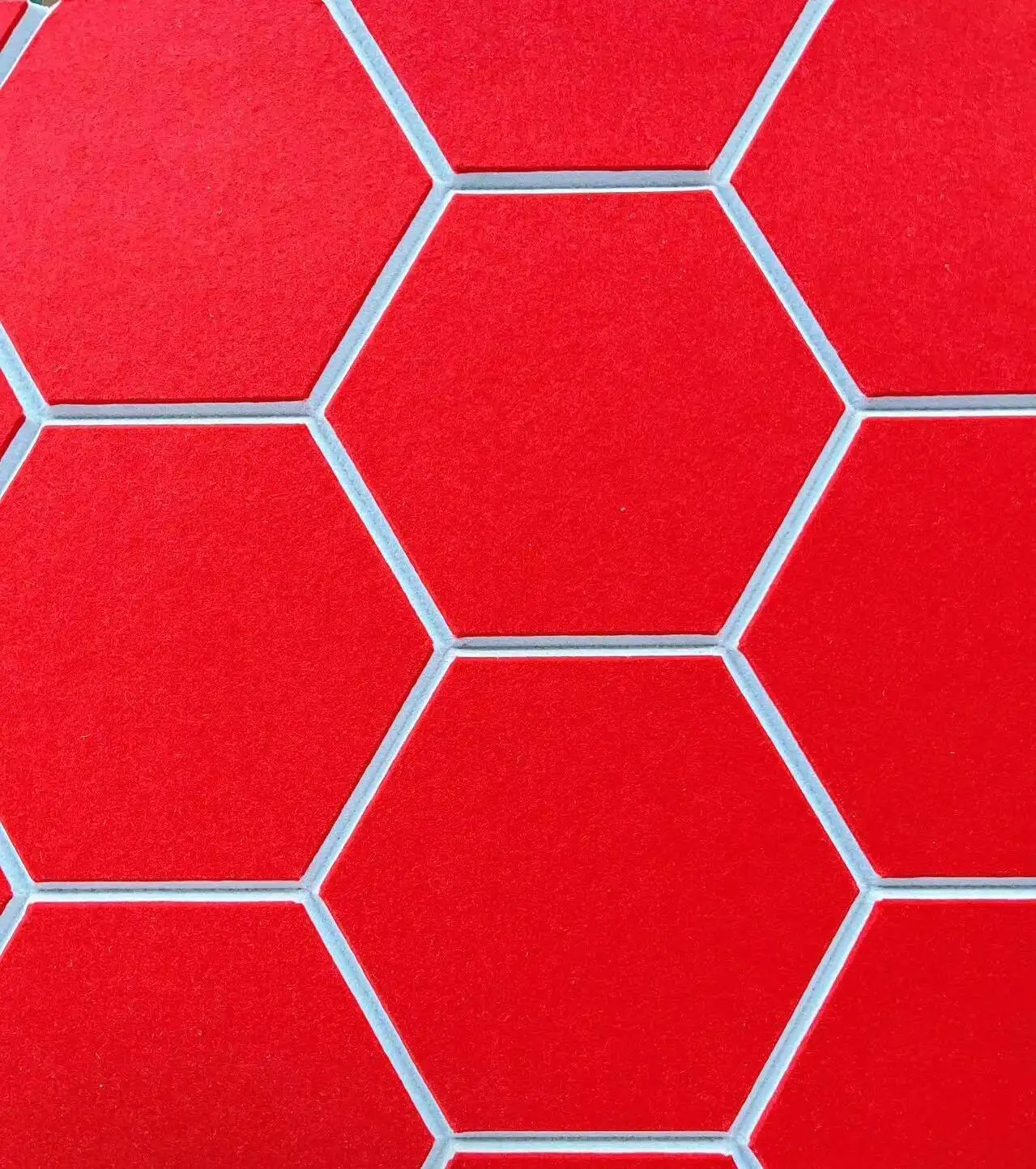

Another advantage of polyester fiber as a sound absorber is its versatility. Unlike rigid materials like foam or wood, polyester fiber can be easily molded into different shapes and sizes to fit a variety of spaces. This flexibility allows for more creative and customized solutions for soundproofing projects.

In addition to its acoustic properties, polyester fiber is also environmentally friendly. It is made from recycled materials, making it a sustainable choice for sound absorption products. This is especially important as more industries are looking for eco-friendly alternatives to traditional building materials.

When it comes to installation, polyester fiber is relatively easy to work with. It can be applied as panels, baffles, or even as insulation in walls and ceilings. Some manufacturers offer pre-made polyester fiber products specifically designed for sound absorption, making it a convenient option for acoustic treatments.

In terms of performance, polyester fiber has been shown to effectively reduce noise levels in various frequency ranges. This makes it a versatile solution for a wide range of soundproofing applications. Whether you are looking to improve the acoustics in a home theater or create a quiet workspace in a busy office, polyester fiber can help achieve your goals.

Overall, polyester fiber is a promising sound absorption material that offers a combination of acoustic performance, sustainability, and versatility. As more people become aware of its benefits, we can expect to see it being used in a variety of settings where noise control is essential. So next time you are considering soundproofing options, don't overlook the surprising sound absorption abilities of polyester fiber.

- Factors Affecting Sound Absorption in Polyester Fiber

Polyester fiber may not be the first material that comes to mind when one thinks of sound absorption, but recent research has uncovered surprising abilities in this synthetic textile. Scientists have been exploring the factors that affect sound absorption in polyester fiber, shedding light on its potential as an acoustic material.

One of the key factors influencing sound absorption in polyester fiber is its structure. Polyester fibers are made up of long chains of molecules that are tightly packed together. This dense structure allows the fibers to effectively trap sound waves, preventing them from bouncing back into the environment. Additionally, the shape and size of the fibers play a role in their sound absorption capabilities. Thinner, longer fibers tend to be more effective at absorbing high-frequency sounds, while thicker fibers are better at absorbing low-frequency sounds.

Another crucial factor in sound absorption is the density of the polyester fiber. Higher density fibers are better at absorbing sound because they have more mass to dissipate the energy of the sound waves. This is why thicker materials, like carpets and drapes made of polyester fiber, are commonly used in soundproofing applications. The density of the fiber can be adjusted by varying the processing techniques used to create it, allowing for customization of the material's sound absorption properties.

In addition to its physical properties, the surface treatment of polyester fiber can also impact its sound absorption abilities. Special coatings or finishes can be applied to the fibers to enhance their acoustic performance. These treatments can alter the surface texture of the fibers, increasing their ability to absorb sound waves. Some treatments can even reduce the reflectivity of the fibers, further improving their sound absorption capabilities.

Furthermore, the arrangement of polyester fibers in a material can affect its sound absorption properties. For example, fibers that are closely packed together will be more effective at absorbing sound than those that are spaced further apart. This is why materials like acoustic panels, which are made up of densely packed polyester fibers, are commonly used in soundproofing applications. The arrangement of fibers can be manipulated during the manufacturing process to optimize the material's sound absorption capabilities.

Overall, polyester fiber has proven to be a surprisingly effective material for sound absorption. By examining the factors that affect its acoustic performance, researchers have uncovered new possibilities for the use of this synthetic textile in soundproofing applications. With further research and development, polyester fiber could become a go-to material for creating quiet and acoustically pleasing environments.

- Comparing Polyester Fiber to Other Sound Absorbing Materials

Polyester fiber is a versatile material that is commonly used in the textile industry for its durability and resistance to shrinking and stretching. However, recent studies have shown that polyester fiber also possesses surprising sound absorption abilities, making it a potentially valuable material for acoustic applications. In this article, we will explore the sound absorption capabilities of polyester fiber and compare it to other commonly used sound-absorbing materials.

When it comes to sound absorption, materials with porous structures are generally more effective at reducing noise levels. Polyester fiber, with its inherently porous nature, is able to trap and dissipate sound waves, thus reducing the overall noise levels in a given space. This makes it an ideal material for use in soundproofing applications, such as in recording studios, theaters, and office buildings.

One of the key advantages of polyester fiber as a sound-absorbing material is its cost-effectiveness. Compared to other materials such as foam panels or fiberglass insulation, polyester fiber is generally more affordable and easier to install. This makes it a practical choice for individuals or businesses looking to improve the acoustics of their space without breaking the bank.

In addition to its cost-effectiveness, polyester fiber also offers superior durability and longevity. Unlike foam panels, which can degrade over time and lose their sound-absorbing properties, polyester fiber is resistant to wear and tear and can maintain its effectiveness for years to come. This makes it a sustainable choice for long-term use in soundproofing applications.

To further explore the sound absorption capabilities of polyester fiber, it is important to compare it to other commonly used sound-absorbing materials. Foam panels, for example, are popular for their lightweight and easy-to-install nature. However, they may not be as effective at absorbing low-frequency sounds as polyester fiber due to their denser composition.

Fiberglass insulation is another common sound-absorbing material that is known for its high performance in reducing noise levels. However, fiberglass can be itchy and irritating to the skin, making it less user-friendly than polyester fiber. Additionally, fiberglass can be more expensive and difficult to install, making polyester fiber a more accessible option for those looking to improve the acoustics of their space.

In conclusion, polyester fiber is a surprisingly effective sound-absorbing material that offers a cost-effective, durable, and user-friendly solution for reducing noise levels. Its porous structure allows it to trap and dissipate sound waves, making it an ideal choice for a variety of acoustic applications. When compared to other sound-absorbing materials such as foam panels and fiberglass insulation, polyester fiber proves to be a practical and efficient option for improving the acoustics of any space.

- Potential Applications for Polyester Fiber in Noise Reduction

Polyester fiber has long been known for its versatility and durability, but recent studies have uncovered a surprising new potential application for this synthetic material: noise reduction. Researchers have discovered that polyester fiber possesses unique sound absorption abilities that make it an ideal candidate for reducing unwanted noise in various environments.

One of the key advantages of polyester fiber in sound absorption is its fibrous structure, which allows it to effectively trap sound waves and prevent them from bouncing around a room. This can help to reduce echoes and reverberation, creating a quieter and more peaceful environment. Additionally, polyester fiber is lightweight and easy to manipulate, making it a practical choice for acoustic panels and other noise-reducing products.

Another benefit of using polyester fiber for sound absorption is its cost-effectiveness. Compared to other sound-absorbing materials like foam or fiberglass, polyester fiber is relatively inexpensive to produce and can be easily mass-produced. This makes it an attractive option for businesses and individuals looking to improve the acoustics of their spaces without breaking the bank.

In addition to its practical advantages, polyester fiber also offers environmental benefits. As a synthetic material, polyester can be recycled and reused, reducing waste and minimizing its impact on the environment. This makes it a sustainable choice for sound absorption applications, providing a greener alternative to traditional noise-reducing materials.

As research into the sound absorption abilities of polyester fiber continues to evolve, new potential applications for this versatile material are being explored. From soundproofing concert halls and recording studios to creating quieter office spaces and homes, polyester fiber has the potential to revolutionize the way we think about noise reduction.

In conclusion, the surprising sound absorption abilities of polyester fiber open up a world of possibilities for improving acoustics in various settings. With its fibrous structure, cost-effectiveness, and sustainability, polyester fiber is poised to become a leading choice for noise reduction solutions in the future. As the demand for quieter and more peaceful environments continues to grow, polyester fiber may just be the answer we've been looking for.

- Future Research and Development in Utilizing Polyester Fiber for Sound Absorption

Polyester fiber is a versatile material that is commonly used in a variety of applications, from clothing to home furnishings. However, recent research has found that polyester fiber also has surprising sound absorption abilities. This discovery has opened up new possibilities for utilizing polyester fiber in sound absorption technologies, and has the potential to revolutionize the way we think about acoustics.

The use of polyester fiber for sound absorption is a relatively new concept, but studies have shown that it has the potential to be just as effective as traditional sound-absorbing materials such as foams and fabrics. One of the key benefits of using polyester fiber for sound absorption is its ability to absorb a wide range of frequencies, making it ideal for use in a variety of settings, from concert halls to office buildings. Additionally, polyester fiber is highly durable and resistant to moisture, making it a long-lasting and cost-effective solution for sound absorption.

Future research and development in utilizing polyester fiber for sound absorption will likely focus on optimizing the material's properties to enhance its sound-absorbing capabilities. This may involve exploring different types of polyester fibers, as well as experimenting with different manufacturing processes to create fibers that are more effective at absorbing sound. Researchers may also look into developing new techniques for incorporating polyester fiber into existing sound absorption technologies, such as acoustic panels and insulation materials.

In addition to improving the sound-absorbing properties of polyester fiber, future research may also explore the environmental impact of using polyester fiber for sound absorption. Polyester is a synthetic material, and its production can have a significant environmental footprint. Researchers may investigate ways to reduce the environmental impact of producing polyester fiber, such as using recycled materials or developing more sustainable manufacturing processes.

Overall, the research on the sound absorption abilities of polyester fiber opens up a world of possibilities for utilizing this versatile material in new and innovative ways. By continuing to explore the potential of polyester fiber for sound absorption, researchers have the opportunity to create more effective and environmentally sustainable sound absorption solutions that can benefit a wide range of industries and applications.

Conclusion

In conclusion, the exploration of the surprising sound absorption abilities of polyester fiber has opened up new possibilities in the field of acoustics. Our 12 years of experience in the industry have given us the knowledge and expertise to further investigate and utilize this innovative material for acoustic solutions. As we continue to push the boundaries of what is possible, we look forward to uncovering even more unique qualities of polyester fiber that can benefit a wide range of industries. Join us on this exciting journey as we continue to explore the endless potential of this versatile material.